POWDER COATING TROUBLESHOOTING

TYPES OF METAL SUBSTRATE

- CRCA (COLLED ROLLED CLOSE - ANNEALED)

|

|

|

|

|

|

- GPSP (GALVANIZED PLANE-SINGLE PASS)

|

|

|

PRETREATMENT (TO CLEAN THE METAL SUBSTRATE)

- PHOSPHATING (FOR CRCA, HR)

|

- CHROMOTIZING (FOR ALUMINIUM)

|

- SHOT BLASTING (FOR HIGH-THICKNESS MATERIAL)

|

- SANDING (FOR HIGH-THICKNESS MATERIAL)

|

PHOSPHATING 7 TANK HOT PROCESS

COLD PROCESS (3 IN ONE)

7 TANK PROCESS WITH CHECK POINT

1. DEGREASING : CLEANING THE SHEET METAL SURFACE GREASE, OILS,SOILS,LUBRICANTS, OXIDE FILMS.

- CHEMICAL : ALKALINE DEGREASER

- TEMPERATURE : 60°C9±10°C

- POINTAGE : AS PER CHEMICAL SUPPLIER

- DURATION : 10-15 MINUTES

2. WATER RESIGNING: CLEANING THE SHEET METAL SURFACE GREASE, OILS, SOILS, LUBRICANTS, OXIDE FILMS.

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5 MINUTES

3. DE-RUSTING: CLEANING THE SHEET METAL SURFACE OF RUST.

- CHEMICAL : RUST REMOVER

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- POINTAGE : AS PER CHEMICAL SUPPLIER

- DURATION : 10 MINUTES

4. DM WATER RESIGNING: CLEANING THE SHEET METAL SURFACE OF RUST.

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5 MINUTES

- PH VALUE : 5 TO 7

5. SURFACE ACTIVATION : SURFACE ACTIVATION FOR PHOSPHATING LAYER

- CHEMICAL : ACTIVATOR (AS PER CHEMICAL SUPPLIER )

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5-10 MINUTES

6. PHOSPHATING

- CHEMICAL : ZINC OR IRON PHOSPHATE

- TEMPERATURE : 40°C+-10°C

- POINTAGE : AS PER CHEMICAL SUPPLIER

- DURATION : 5-10 MINUTES(ACCORDING JOB)

7. DM WATER RESIGNING

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5 MINUTES

- PH VALUE : 5 TO 7

CHROMOTIZING PROCESS

NON-CHROMOTIZING PROCESS

CHROMATING PROCESS WITH CHECK POINTS

1. DEGREASING : CLEANING THE ALUMINUM SURFACE OF GREASE, OILS, SOILS AND LUBRICANTS FILMS.

- CHEMICAL : ACID DEGREASER

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- POINTAGE : AS PER CHEMICAL SUPPLIER

- DURATION : 10-15 MINUTES

2. DM WATER RESIGNING

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5-7 MINUTES

- PH VALUE : 5 TO 7

3. ETCHING : THE PURPOSE OF ETCHING PROCESS IS TO REMOVE THE THIN NATURAL OXIDE LAYER ON THE SURFACE BEFORE THE CHROMATING.

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- POINTAGE : AS PER CHEMICAL SUPPLIER

- DURATION : 5 MINUTES

4. DM WATER RESIGNING

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5 MINUTES

- PH VALUE : 5 TO 7

5. CHROMATING

- CHEMICAL : YELLOW & GREEN CHROME

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5 MINUTES

- PH VALUE : 4 TO 5

6. DM WATER RESIGNING

- TEMPERATURE : AMBIENT ROOM TEMPERATURE

- DURATION : 5 MINUTES

- PH VALUE : 5 TO 7

SUBSTRATE DRYING

- AIR

- OVEN (TEMPERATURE 100 TO 120?C)

GUN BOOTH APPLICATION (MANUALLY & AUTOMATIC)

TYPES OF GUN:-

- CORONA (MOSTLY THIS GUN USED)

- TRIBO (FOR INTRICATES

SHAPES)

TYPES OF OVENS (BATCH TYPE & CONVERISED)

- GAS FIRED

- DIESEL FIRED

- ELECTRIC FIRED

- BIO-FUEL FIRED

PROBLEMS & SOLUTIONS

CLASSIFICATION OF PROBLEMS

POWDER RELATED

APPLICATION RELATED

- FLUIDIZATION

- GUN SPITTING

- COVERING

- FILM THICKNESS

- RECYCLE POWDER

FINISH RELATED

- GLOSS

- FINISH

- COLOR CHANGE

- PIN HOLES

- ORANGE PEEL

MECHANICAL & CHEMICAL TEST

- IMPACT TEST

- BAND TEST

- CROSS HATCH TEST

- SST TEST

- QUV TEST

LUMPS FORMATION

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- THE POWDER HAS BEEN STORE FOR TOO LONGER TIME OR TEMP TOO HIGH FOR

STORAGE

|

- KEEP POWDER COOL & DRY AREA.

- FILTER THE POWDER

|

GUN SPITTING

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

-

POOR FLUIDIZATION IN POWDER HOPPER PUMP & BLOCKED HOSES NOT ADJUSTED PROPERLY

- PUMP & BLOCKED HOSES NOT ADJUSTED PROPERLY

|

- INCREASE OR DECREASE THE FLUIDIZING AIR TO HOPPER

- CHECK BOTTOM OF HOPPER AND MEMBRANE FILTER

- INCREASE ATOMIZING/ DIFFUSER AIR

- CHECK ALL AIR TUBE CONNECTIONS FOR LEAK

- REDUCE THE AMOUNT OF RECLAIM POWDER

|

POOR PENETRATION (COVERING)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- INSUFFICIENT POWDER

- POOR EARTH

- INCORRECT SPRAY PATTERN

- VOLTAGE TOO FINE

- POWDER TOO FINE

|

- INCREASE THE PUMP FLOW-RATE PRESSURE

- CLEAN THE HOOK AND RACKS, ALSO CHECK AND IMPROVED GROUNDING

- TRY DIFFERENT NOZZLES FOR DIFFERENT SURFACE

- REDUCE GUN VOLTAGE (Kv)

- REDUCE THE AMOUNT OF RECLAIM POWDER

|

COVERAGE

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- POWDER DELIVERY RATE TO HIGH (EFFECT-THICKNESS)

- SHAPE OF SUBSTRATE

- INCORRECT SPRAY COATING METHOD

- RECYCLE POWDER EFFICIENCY

- POOR EARTH

|

- POWDER DELIVERY RATE DECREASED (CONTROL-THICKNESS)

- DIFFERENT SHAPE CHANGE AREA

- CHECK GUN DISTANCE & COATING METHOD

- CHECK RECYCLE POWDER %

- CLEAN HOCKS , HANGER & IMPROVED GROUNDING

|

GUN PARAMETERS FOR POWDER

| FINISH

|

SMOOTH

|

STRUCTURE

|

TEXTURE

|

METALLIC

|

| CHARGING (Kv)

|

70-90

|

70-100

|

70-80

|

50-60

|

| AIR (Kg/Cm3)

|

1.5-4.0

|

1.0-2.5

|

1.5-4.0

|

0.5-1.5

|

| POWDER

|

As Per Required

|

As Per Required

|

As Per Required

|

As Per Required

|

| CURRENT(????A)

|

20-40

|

20-40

|

20-40

|

20-30

|

| FLUIDIZATION(Kg/Cm3)

|

As Per Required

|

As Per Required

|

As Per Required

|

As Per Required

|

FILM THICKNESS TOO LOW OR TOO HIGH

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- POWDER DELIVERY TOO LOW

- INSUFFICIENT COATING TIME

- FARADAY CAGE EFFECT

- POOR EARTHING

- POWDER OUTPUT TOO HIGH

|

- INCREASES COATING TIME OF COMPONENT

- ADJUST THE GUN VOLTAGE & OTHER PARAMETERS

- CLEAN HOOKS & RACKS

- TURN DOWN PUMP PRESSURE & MOVE GUN FARTHER AWAY FROM THE PARTS REDUCE GUN VOLTAGE

- REDUCE TIME OF COMPONENT COATING TIME

|

CRATERS & PIN HOLES

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- OIL & OTHER CONTAMINATION ON PARTS

- CONTAMINATED COMPRESSED AIR

- CONTAMINATED POWDER

- MOISTURE IN AIR

- SILICON CONTAMINATION

- POOR SHEET QUALITY

|

- CHECK CLEANING AND PRETREATMENT

- ENSURE COMPRESSED AIR IS FREE FROM OIL

- CLEAN THE EQUIPMENT AND RECHARGE WITH FRESH POWDER

- DRAIN OUT THE WATER FROM COMPRESSOR

- REMOVE LOCATED SOURCE POINT

- CHOOSE SPECIAL DEGASSING GRADE POWDER MICRO PINHOLE IN GPSP SHEET

|

GLOSS (TOO HIGH OR TOO LOW)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- CURE OVEN TEMP TOO LOW

- CURE OVEN TEMP TOO HIGH

- OVEN CYCLE TIME LOW & LONG

- CONTAMINATION WITH INCOMPATIBLE POWDER

|

- INCREASE THE OVEN TEMP

- DECREASE THE OVEN TEMP

- ADJUST LINE SPEED & CURING TIME

- REMOVE ALL CONTAMINATED POWDER THOROUGHLY CLEAN ALL EQUIPMENT THEN USE FRESH POWDER

|

POOR ADHESION (CHIP-OFF)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- POWDER UNDER CURE

- POOR PRETREATMENT (OIL & DIRTY SURFACE)

- HIGH COATING

- PREHEAT AFTER PRE-TREATMENT PROCESS

|

- INCREASE THE TEMP

- CHECK THE PRETREATMENT PROCESS

- ADJUST COATING AS PER PRODUCT STD

- CHECK CONDITION & SUGGESTED FOR PREHEAT

|

COLOR VARIATION

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- FILM THICKNESS VARIATION

- DIFFERING SUBSTRATES & SUBSTRATE COLOR

- OVER CURING OF POWDER COATING

|

- ASSURE CONSTANT FILM THICKNESS

- USE SUBSTRATE OF SAME TYPE FOR COMPARISONS

- OBSERVE CURING PARAMETERS OF POWDER MANUFACTURER

|

COLOR FADING

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- CLEANING METHOD VERY POOR

- POOR PAINT FILM ADHESION

- SMALL PIN HOLE & DEGASSING ON FINISH

- SUN UV RAYS, MANY POLLUTANT SECTION ARE FASTER FADE SOME PLACE

- CHOOSE WRONG CHEMISTRY POWDER

- COLOR HAS A LIMITED LIFE EXPECTANCY

|

- CHECK PRE-TREATMENT PROCESS

- CHECK TEMPERATURE

- CHEEK PINHOLE SOURCE

- DISCUSS CONDITIONS WITH MANUFACTURE

- CHOOSE OUTDOOR DURABILITY ARCHITECTURAL GRADE POWDER

- CONTACT MANUFACTURE

|

STRUCTURE PATTERN

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- FLAT PATTERN

- SMALL PATTERN (PIN HOLE)

|

- ADJUST THE AIR PRESSURE & LOWER THICKNESS

- INCREASE THICKNESS. LONG CURING TIME

|

DUSTING (FOREIGN PARTICLE IN FILM)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- SUBSTRATE SURFACE IS DIRTY

- BOOTH AREA IS NOT CLEAN

- POWDER IS TOO COARSE OR NOT SIEVED

|

- CHECK THE PRETREATMENT PROCESS

- CLEAN THE SUBSTRATE BY AIR CLEANING

- CLEAN THE BOOTH AREA. SIEVE ALL RECLAIM POWDER

|

ORANGE PEEL (POOR FLOW)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- FILM THICKNESS IS TOO HIGH OR TOO LOW

- VOLTAGE TOO HIGH

- HEAT CYCLE OF THE TOO SLOW

- AIR PRESSURE IS TOO HIGH

|

- CHECK SYSTEM PARAMETERS

- OPTIMIZE VOLTAGE

- DETERMINE THE HEAT UP CURVE AND INCREASE

- REDUCE THE AIR PRESSURE

|

CLOUD PROBLEM (CARBON LAYER) IN FINISH

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- CORROSIVE URBAN ATMOSPHERE

- UNIFORM EXPOSURE TO AIR & ITS POLLUTANTS

- COATING DEFECTS OR COATING DAMAGE

- UNCURED SUBSTRATE

- CHLORIDE CONTAMINATION ON PHOSPHATE FILM

- DAMP MOISTURE FILMS OVER METAL SURFACE

- WET FILMS OF DEW & RAINWATER

|

- USE CORROSION RESISTANT METAL OR ALLOY

- REDUCE ATMOSPHERIC POLLUTANTS

- DO REGULAR SURFACE CLEANING

- CHECK CURING TEMPERATURE REGULARLY

- AVOID COATING DEFECTS

- USE SUITABLE CORROSION INHIBITORS

- COATED SUBSTRATE PACKING AREA SHOULD BE DRY

|

CORROSION (RUST)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- CORROSIVE URBAN ATMOSPHERE

- UNIFORM EXPOSURE TO AIR & ITS POLLUTANTS

- COATING DEFECTS OR COATING DAMAGE

- UNCURED SUBSTRATE

- CHLORIDE CONTAMINATION ON PHOSPHATE FILM

- DAMP MOISTURE FILMS OVER METAL SURFACE

- WET FILMS OF DEW & RAIN WATER

|

- USE CORROSION RESISTANT METAL OR ALLOY

- REDUCE ATMOSPHERIC POLLUTANTS

- DO REGULAR SURFACE CLEANING

- CHECK CURING TEMPERATURE REGULARLY

- AVOID COATING DEFECTS

- USE SUITABLE CORROSION INHIBITORS

- COATED SUBSTRATE PACKING AREA SHOULD BE DRY

|

USE OF RECYCLE POWDER

- MAINTAIN USE OF RECYCLE POWDER PERCENTAGE WITH MAXIMUM (70:30) RATIO. IF WE USE WITH HIGHER RATIO THAT CAUSE PROBLEM IN FINISH.

- USE RECYCLE POWDER ONLY AFTER SIEVING. IF WE USE WITHOUT SIEVING THAT CAUSE DUSTING.

- COLLECT THE RECYCLE POWDER SEPARATE BOX & COVER PROPERLY OTHERWISE FACE IN PINHOLE PROBLEM.

COLOR VARIATION (IN METALLIC)

| POSSIBLE CAUSE

|

SUGGESTED SOLUTION

|

- HIGH CHARGING

- HIGH AIR PRESSURE

- GUN DISTANCE TOO HIGH OR TOO LOW

- COLOR VARIATION IN RECYCLING

|

- REDUCE THE CHARGING TO BELOW 60 KV

- OPTIMIZE THE AIR PRESSURE

- ADJUST THE GUN DISTANCE

- MAINTAIN 90/10 RATIO USE OF RECYCLE POWDER

|

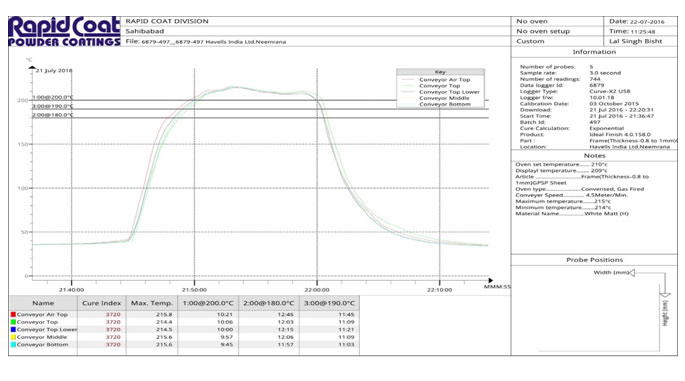

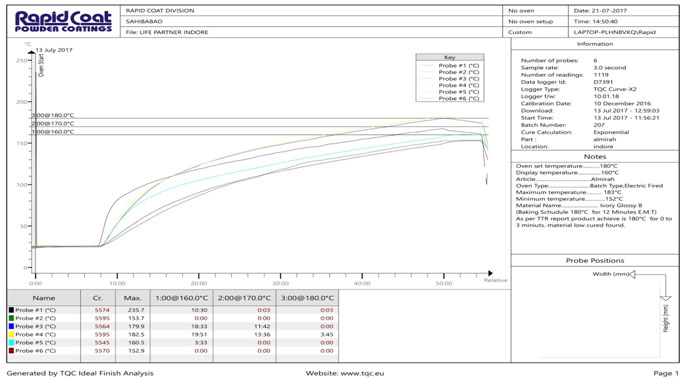

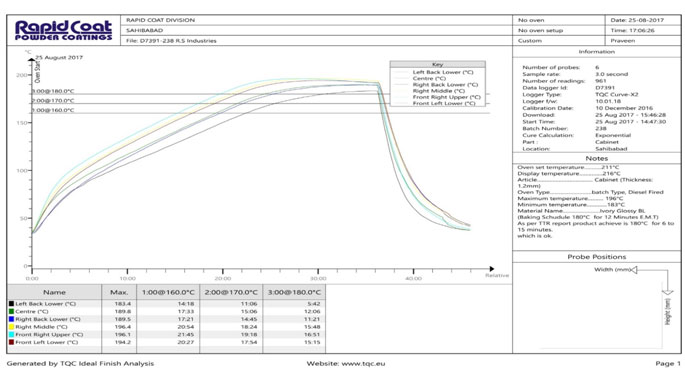

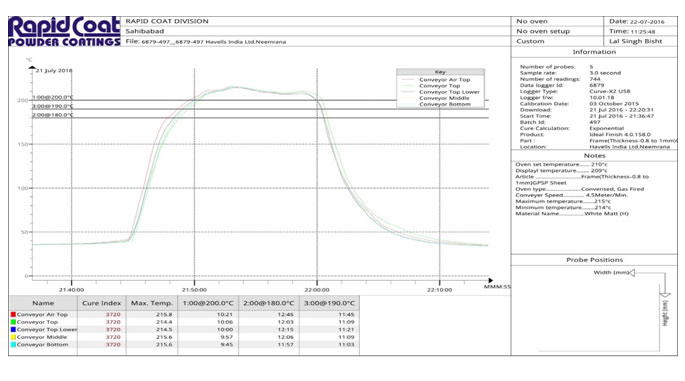

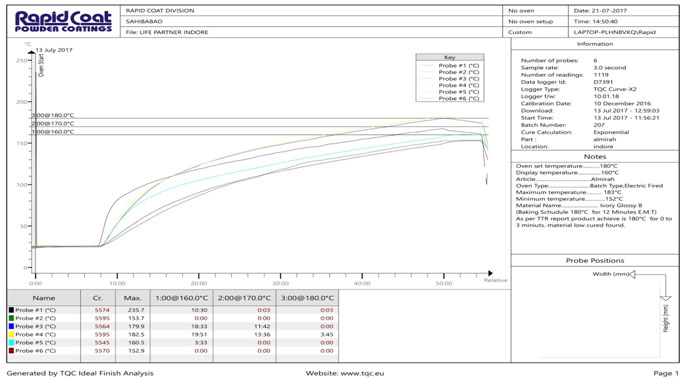

TTR (TRAVELLING TEMPERATURE RECORDER)

-

DATA LOGGER : TTR data logger is a portable measuring

device that is capable of autonomously recording temperature over a

defined period of time. The digital data can be retrieved, viewed and evaluated

after it has been recorded.

- PROBE : The type K is the

most common type of thermocouple.

- INSULATION BOX : It insulate heat to protect data logger.

TTR GRAPH RESULT NOT OK

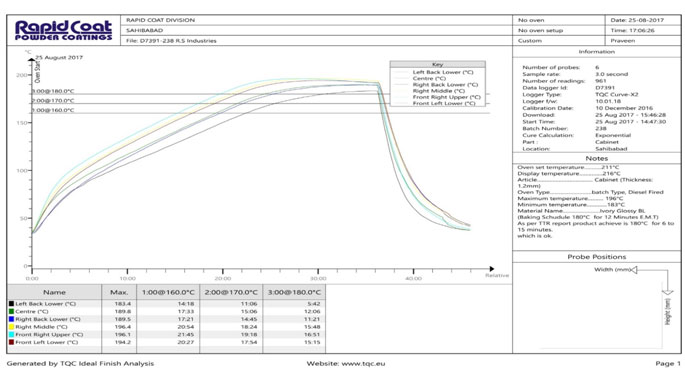

TTR GRAPH RESULT OK

TTR RESULTS (CONVEYOR OVEN)